Vertical Lathe: What it is, Advantage and Operation

Have you ever wondered how the most complex and precise metal parts are manufactured? Vertical lathes are the key. Discover their operation, advantages and applications in this essential article for the industry. Don't miss it!

Have you ever wondered how the most complex and precise metal parts are manufactured? Vertical lathes are essential machines in industry for this purpose. That's why we'll explain everything you need to know about vertical lathes, from how they work to their most common applications.

What is a vertical lathe?

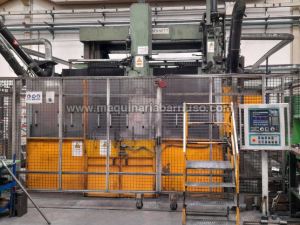

A vertical lathe is a machine tool used for machining large and heavy parts. Unlike horizontal lathes, where the rotation axis of the workpiece is in a horizontal position, in vertical lathes, the rotation axis is in a vertical position. This arrangement makes it possible to work with very heavy and large diameter workpieces with greater stability and precision.

Parts of a vertical lathe

A vertical lathe consists of several essential parts:

- Rotary table: Where the workpiece is placed.

- Main spindle: Rotates the rotary table and, therefore, the workpiece.

- Toolholder: Holds and moves the cutting tools.

- Numerical control (CNC): Computerized system that controls the movements of the lathe.

How does a vertical lathe work?

The operation of a vertical lathe is relatively simple. The workpiece is clamped on the rotary table, which rotates around the vertical axis. As the table rotates, the cutting tools, controlled by the tool holder and CNC system, move over the workpiece to shape it. Thanks to the vertical arrangement, the cutting forces are distributed so that the machine can handle very large and heavy workpieces without losing accuracy.

Advantages of the vertical lathe

Vertical lathes offer several significant advantages:

- Stability: The vertical arrangement and the robustness of the rotary table make it possible to work with heavy workpieces without risk of shifting.

- Accuracy: The design minimizes vibrations, resulting in more precise machining.

- Versatility: They can work with a variety of materials and shapes, making them ideal for a variety of industries.

Common applications for vertical lathes

Vertical lathes are used in a wide range of industries. Some of the most common applications include:

Aerospace industry

In the aerospace industry, precision is crucial. Vertical lathes are used to manufacture engine components and other critical parts that require high precision and tight tolerances.

Automotive industry

In automotive manufacturing, vertical lathes are essential for producing engine parts, wheels, and other components that need to be perfectly symmetrical and strong.

Wind energy

Wind turbine components, such as bearings and housings, are manufactured on vertical lathes because of their large size and the need for high precision.

Shipbuilding

Shipbuilding also benefits from vertical lathes to manufacture large and heavy components with high precision, such as propellers and shafts.

How to choose a vertical lathe?

If you are considering purchasing a vertical lathe, it is important to consider several factors:

- Rotary table size: Depending on the size of the parts you plan to machine.

- Load capacity: Make sure the machine can handle the weight of your parts.

- CNC system: Verify that the numerical control system is advanced and easy to use.

- Brand and technical support: Opt for recognized brands that offer good technical support.

Why choose a used vertical lathe?

Although vertical lathes are essential in many industrial processes, their cost can be a challenge for certain budgets. However, purchasing a used vertical lathe offers an affordable alternative for those looking to maximize efficiency without compromising quality.

Some advantages of considering the purchase of a used vertical lathe are:

- Price: Being a used machine, its cost is considerably lower compared to a new one. This allows even the tightest budgets to have access to high quality equipment.

- Reliability: The fact that the lathe has been used before is proof of its functionality and durability. Knowing its history of use provides confidence in its performance and results.

- Immediate availability: By opting for a used vertical lathe, you can have it in your shop or factory immediately. In contrast, waiting for a new lathe can mean production delays that affect your business.

|

|

| MANDRINADORA TOS WHN | MANDRINADORA JUARISTI |

Vertical lathes are indispensable tools in the manufacture of large and heavy parts with high precision. Their stability, precision and versatility make them ideal for a wide variety of industries. If you would like more information on how vertical lathes can improve your production process, do not hesitate to contact us at Maquinaria Barriuso. We are here to help you find the perfect solution for your industrial needs.

Latest articles

April 2024

April 2024

Tipos de viradores de soldadura

...

March 2024

March 2024

Conoce todo sobre las plegadoras de chapa

...

March 2024

March 2024

¿Qué son los centros mecanizados y cuáles son sus funciones?

...